The modern warehouse is far more than a static storage space. It is a intricate hub of activity where accuracy is king. At the heart of this organized chaos lies the order fulfillment system. This is not a single piece of equipment but rather a integrated ecosystem of technology, procedures, and physical tools. Together, these components work in concert to turn a customer click into a boxed order on its way to a satisfied customer.

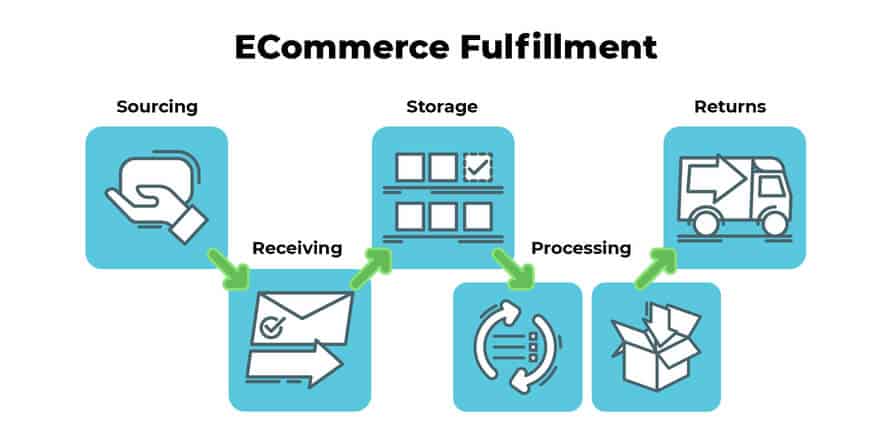

The modern warehouse is far more than a static storage space. It is a intricate hub of activity where accuracy is king. At the heart of this organized chaos lies the order fulfillment system. This is not a single piece of equipment but rather a integrated ecosystem of technology, procedures, and physical tools. Together, these components work in concert to turn a customer click into a boxed order on its way to a satisfied customer.At its most essential level, a warehouse fulfillment system is built upon the central platform: the WMS. This is the command center that orchestrates all activities within the four walls. A robust WMS monitors every single item in constantly. It knows its exact location, stock level, and travel path through the facility. When an order is placed, the WMS instantly logs it. It then generates the required instructions to fulfill that order as accurately as possible.

These instructions appear in the real-world realm through various order selection strategies. A common method is discrete picking, where a worker completes one entire order at a time. For greater throughput with many small items, multi-order picking is often employed. Here, a picker gathers items for several orders in one trip through a designated zone of the warehouse. Another advanced method is zone picking. In this system, an order moves from one station to the next, with workers in each zone picking only the items located in their assigned area. The WMS optimizes which method is best for each wave of work.

Technology plays a huge role in guiding the pickers themselves. light-directed picking use digital displays on shelves to indicate the correct location and quantity of an item to pick, dramatically reducing errors and search time. Similarly, Put-to-Light systems are used at packing stations to tell workers where to place each picked item for a specific order. In the most advanced warehouses, robotic retrieval bring the inventory shelves directly to a stationary picker via mobile racks. This removes walking time and boosts productivity to remarkable levels.

After items are picked, the order moves to the packing area. Here, the system facilitates accuracy once more. Scanning each item against the order is a common step to prevent errors before the box is sealed. The WMS often communicates with dimensioning systems. This software can automatically determine the smallest possible box or mailer for the contents. It also calculates the least expensive shipping rate and produces the carrier label instantly. This seamlessness of integration streamlines the process and eliminates manual data entry mistakes.

Finally, the dispatch phase is also governed by the system. Automated sortation systems can read labels and route packages to the correct shipping lane based on service level. The WMS finalizes the order status, sends a tracking number to the customer, and deducts inventory levels in the central database. A modern fulfillment system even manages the reverse logistics, creating return labels and instructing returned items back into stock.

In summary, a well-designed warehouse fulfillment system is the operational genius behind efficient E-commerce fulfillment. It transforms a warehouse from a storage facility into a strategic asset. By orchestrating people, processes, and technology, these systems ensure high levels of speed, accuracy, and scalability. For any business looking to excel in the age of instant gratification, investing in these systems is not a luxury. It is a necessary requirement for meeting customer expectations and achieving profitable, sustainable growth.